Undertaking a self build will typically yield a significant capital gain advantage, over buying from the existing market. What’s more you will have a bespoke building that’s tailored to the needs and tastes of you and your family.

However the pitfalls in this approach are well documented, just watch any Grand Designs episode and you will often see budgets spiral out of control and relationships strain. So how can you take the pain out of this process?

We believe that undertaking a design and build package using a timber frame kit home can help de-stress the whole process and infer real advantages over a conventional brick and block construction.

1. Continuity

By undertaking a design and build contract such as our offering, you can be sure the architect is designing a building that will work in a practical context and has a strong motivation to keep costs down. Furthermore by engaging an architect such as SDC on a design and build contract you can avoid paying VAT on your design fees. We will be with you every step of the way to ensure your project is successful.

2. Speed

By choosing offsite manufacture and timber frame you can save huge amounts of time. Our timber frame system and Passive Slab foundation can be manufactured simultaneously. This way a kit home can be manufactured in a fraction of the time of a conventional build and is not subject to the same weather constraints. Once our kit home flat packs arrive on site, they are assembled in a matter of days. This speed also reduces the prelim costs of maintaining the site.

3. Sustainability

Timber frame construction is naturally more suited to reducing a buildings energy use. More insulation can be incorporated into a thinner wall and our unique twin-wall design eliminates thermal bridges. The result is one of the most energy efficient building envelopes on the UK market currently. We provide airtightness services to gaurantee passivhaus performance or below. Another advantage is that our timber frame system has significantly lower embodied CO2 emissions than a block work construction. By using a lightweight timber frame, you can massively reduce the amount of expensive and high carbon concrete in the foundations.

4. Ease

By using one port of call for your project you can massively simplify the process. This enables you to get a much clearer handle on build costs from an early stage, as we offer both slab foundation and timber frame services, you have to deal with fewer subcontractors and can ensure a quality assurance process from the ground up. Our system also allows easy integration of MVHR systems through metal webbing joists, and provides a service void for easy installation or mechanical and electrical services. Our system also allows for precise installation of dry lining and second fix elements with tolerances of 2mm or less.

5. Cost

All the above reasons show clearly how building kit home using offsite timber frame methods can save you thousands on your build project. With lower fees and associated costs combined with up to a 90% reduction in energy bills from building using our passive build package, and much easier follow on for finishing work, it’s no wonder this type of build is the fastest growing market in the UK.

]]>The principles of the passivhaus or passive house concept are based on a simple postulation. That conserving heat energy, through insulation and reducing air permeability, is a more resource efficient means of maintaining a comfortable internal temperature, than converting higher forms of energy into heat. This has some strong grounding in basic physical principles, although achieving this requires our buildings to halt the essential entropic tendency, for heat energy to seek a state of equilibrium.

Great innovation in the levels of building fabric performance alongside a greater understanding of building physics, and mechanical ventilation technology, now means we are now able to maintain passivhaus homes without formal heating systems, even at high latitudes.

A central tenet of the passivhaus approach is that it is also almost always cheaper to conserve heat, rather than create it, using other low carbon forms of energy. Thus this leads us to consider the two key goals of such an approach from an energy use perspective:

- Conserve heat, reducing the cost of heating buildings, in an era of rising fuel prices and fuel poverty

- Thus reduce combustion of greenhouse gases that are the major contributor to global climate change

This logic has informed the ‘energy hierarchy’, that now governs the approach to residential and commercial energy strategies in UK construction. However we must consider that this truism, does not always hold. I’m sure the reader can think of many examples where insulation methods such as bespoke high performance passivhaus windows, or tricky external insulation detailing, is far more expensive than installing solar PV panels for the same CO2 savings.

Indeed with PV panels continuing to fall in cost past £1k/kW, and the majority of passivhaus projects in the UK remaining for private self build enthusiasts, we have to ask ourselves what is passivhaus for and where is it going?

Almost uniquely in environmental problems, climate change and the impact of CO2 emissions are global in nature. Therefore unlike other environmental pollution problems, small localised reductions in emissions will have no impact, without the bigger picture changing.

Therefore we must consider that if the passivhaus standard is to deliver on the 2 key goals identified, it must achieve the following:

- Be able to demonstrate the approach presents the most cost effective means of reducing domestic energy consumption and CO2 emissions

- Be delivered at a scale that will make a significant impact to the climate change issue

There are some encouraging signs as the passivhaus standard is being adopted in a number of social housing schemes of increasing scale across the UK and elsewhere. Many in the mainstream industry see passivhaus as a method that will never go mainstream, instead it will continue to inform conventional building standards by demonstrating best practice. However the key problem with this argument are that to see the cost benefits of adopting passivhaus principles, you really have to take thermal performance to a level where a wet central heating system is no longer needed. This allows for the estimated 15% increase in build cost from a passivhaus to be offset by saving £10k+ on a central heating system. So unless we can get a building down to around 10W/m2 peak heating load, we are stranded in an expensive place from a specification point of view.

The more schemes that demonstrate the standard can be achieved at a parity with a Part L compliant specification, the stronger this argument will become. Perhaps a key driver of this scenario is for local authorities to begin to specify the PH standard, vis a vis the code for sustainable homes, pre-housing standards review. However in an era of deregulation this seems increasingly unlikely.

Without a deployment for the masses passivhaus could remain a niche standard for enthusiast and dare I say it the borgousie, with the time and money to undertake their own ‘grand design’. The standard has great potential and elements that could enable deployment at mass scale, however we need to begin thinking in a more strategic way if this potential is to be realised. Everyone deserves a healthy and comfortable place to live, therefore policy-makers should aim high, and consider how Passivhaus might make a contribution a few orders of magnitude more than it has currently.

Quo Vardis Passivhaus?

Donal Brown

Sustaianbilty Director SDC Ltd

]]>

The Crystal London, a LEED platinum and BREEAM Outstanding sustainable building

“I don’t think that sustainability is a design aesthetic, any more than having electricity in your building…It is an ethic, a basic consideration that we have as architects designing buildings” Robert Stern, Dean of Yale School of Architecture- Environment Yale magazine 2010.

Stern illustrated his comments with a picture of a “green” Dutch garage with LEED (Leadership in Energy and Environmental Design) certification, and while it might have seemed crass to extol a temporary parking garage as an icon of sustainable architecture; there is an larger irony here as Stern also prophesised

“In ten years we are not going to talk about sustainability anymore, because it is going to be built into the core processes of architecture”

I remember thinking similar things in the mid 1980s as a fellow traveller with Earth Resources Research Ltd and as a committed local authority community architect but then having real difficulty in a planning permission because the proposed additional external insulation would move the building line 100 mm nearer the road 15 (a project for external insulation combined with new windows and heating systems on an East London estate)

BREAM and CSH the LEED equivalents in Britain are both central to some political ideas on sustainability but are more observed in the breach and seen by many architects and clients as a costly hindrance and by climate change deniers as on a par with wind farms, Yet it’s also true that their bureaucratic complexity means its difficult to sell them as enabler for good building that provide sustainable living. Passivhaus at least has the advantage of being clearer and focussed on effecting energy consumption and the cost of living in buildings although there still seems to be too many opportunities to add unreasonable administrative costs.

They undeniably add non-productive cost in planning process to building costs and for the public sector a cost they have to build in that others might avoid. For some planners they do provide a nice complex set of rules to administer so they can avoid the more difficult processes of creative thinking in creating sustainable environments.

The “3 tier” changes to the Building Regulations and the continuing get outs in Bream and the shenanigans on Zero Carbon are a dangerous continuation of the Its more than ironic that the Government proposal for providing homes for first time buyers sees 20% cost reductions in ignoring its own

Stern’s 10 year prophecy seems to be going wrong in the typical way of western “bureaucracies”. Yet most young architects and environmental scientists I meet do have sustainability is part of the their mindset; I fear for them unless we can change direction and that sustainability becomes part of societies mindset not a 3 tier circus nor a bureaucratic justification exercise or “how can we avoid it game”

Bill Brown RIBA – Managing Director – SDC ltd

]]>With the exception of the South of Ireland and perhaps parts of Scotland in these islands sustainable kit homes are seen as experimental, expensive and not affordable, certainly not for the mainstream (whether for sale or rent).

SDC and its partners aim to disprove two notions in providing sustainable kit homes.

- That sustainability and Passive build methods need to be comparatively expensive.

We have already proved that our kit home system can provide cost effective even on the most difficult of small brownfield sites. The kit build system provides a very shallow passive standard foundation, which with the below slab insulation, allowing the foundations to be complete within days. Our timber frame kit homes are manufactured offsite and therefore can deliver large savings in cost, and can be delivered at a competitive price with conventional methods, but with much higher energy performance.

2. The appearance of the houses has to be plain.

We can design and supply a kit home with any external finish the client wishes, as the highly insulated walls provide a box which can be hung with any eternal finish, including non-structural brick or stone work as well as render, panels, vertical tiling, wood cladding

These flat pack homes can be wind/water tight after 4/5 weeks and construction times can be significantly cut compared to conventional build methods.

]]>Our Kit Homes design and build process provides total assurance and peace of mind for the self-builder, or commercial client, looking to achieve a low energy build or Passivhaus standard . We take architects plans and develop realized kit house designs using the latest CAD software, all structural loading calculations are undertaken by our in house engineers.

Site Preparation

Prior to delivery of the kit home and passive slab foundation system the client or groundworks contractor strips the site to the required levels and installs the first 150mm of hardcore. At this time it is also advisable to install the drainage connections and services for the building, along with the footings for the roadway or paving and any retain walls or structures that are required.the required levels and installs the first 150mm of hardcore.

Passive Slab Foundation

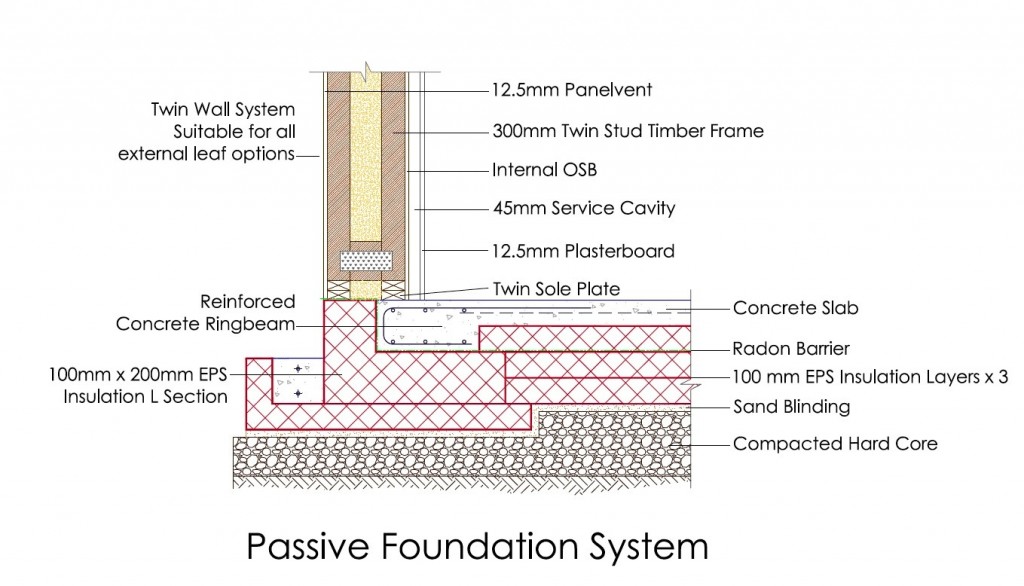

Our kit home build team will arrive and install the next 50-100mm of blinding material and pack it down to ensure that the building is built on an entirely level platform. Unlike conventional build methods we aim for tolerances of 2mm or less. At this time our passive slab contractors will install pipework or drainage connections to your design. By feeding build services though the foundation this enables the most airtight and neat solution possible, an essential choice for an airtight Passivhaus or low energy kit builds.

Our foundation is formed from structurally reinforced Expanded polystyrene (EPS) which is machined offsite. This then forms a permanent insulated raft foundation for the Passive kit home and achieves a u-value of 0.10w/m2k. We then install a radon barrier that also acts as a damp proof membrane.

If your self-build house or commercial project has a masonry exterior we will also install a reinforced ring beam. Once all is prepared the concrete pour can begin. Our eco builders take extra care to ensure that the passive slab is power floated to be flat as a billiard table. We require these extremely fine tolerances to be adhered to so that when the flat pack timber frame kit home arrives almost no settlement occurs.This is essential when precision engineering a kit home in this way using modern methods of construction (MMC).

Flat pack Kit Home – Superstructure

The beauty of our kit home system is that the foundation passive slab and flat pack timber frame walls can undergo manufacture simultaneously

The Timber frame wall cassettes are manufactured from engineered European softwood in our factory in county Tipperary. This form of kit build construction enables great speed as well as precision and minimal waste and can typically cut down you build time from 4-8 weeks.

The unique twin-wall timber frame design enables an extremely low u-value 0.12w/m2k as more insulation fills the gaps and repeating thermal bridges are minimised. The timber frame is clad with engineering grade OSB on the internal face and battens to form the 38mm service cavity. On the external face we use Panel vent and a breather membrane for added vapour protection.

The timber frame flat pack cassettes are loaded on to low loaders and transported to site. The kit home erection team make short work of unloading the flat packs, and begin to erect the ground floor. Typically two to three stories of the building can be erected in one day. The timber frame is clad with engineering grade OSB on the internal face and battens to form the 38mm service cavity. On the external face we use Panel vent and a breather membrane for added vapour protection.

The floor is made up from metal webbing joist that help provide sound insulation and allow mechanical and electrical services or MVHR to pass through the floor. We also provide all internal studs loose to enable boarding of the ceilings to use full boards and superior sound protection between rooms.

Warm roof kit home cassettes can be lowered into position with ease. Or where the roof is cold typically we use our own engineered roofing trusses, both achieve 0.10w/m2k We finish the roof by providing waterproof felt an batten ready for tiling slating or a green or metal roof finish.

Windows

Once the timber frame kit house superstructure is complete, Passivhaus triple glazed windows can be installed.

We specify triple glazed Passivhaus certified windows as standard <0.8w/m2k. These units come in a range of price points from UPVC, Solid aluminium, Alu-timber clad and solid timber options.

These high performance Passivhaus windows are an essential component of our low energy kit builds as windows and doors loose a great deal of heat. We specify Passivhaus certified windows that are very affordable and are manufactured in the UK.

Insulation

Once windows are installed our kit home build team then pump high density cellulose Warmcell insulation into every void and space in the timber frame kit shell. Studies have shown this insulation method has less of a thermal performance gap caused by air spaces than conventional insulation slabs and batts, where gaps are more common.

Airtightness

Our kit build team undertake highly diligent airtightness detailing, using lifetime guarantee SIG and Intello tapes and membranes. We guarantee after first fix works are complete by us that the building will achieve Passivhaus airtightness standards of <0.6 ach/hr @ 50 Pa, and we include the blower door test as part of our build package.

Next Steps

Once the Passive Build frame package is complete the finishing contractors can undertake the internal and external fit out. We have a range of main contractor partners depending on you region and can discuss a turkey solution to your low passive kit home.

Building is air and water tight with insulation and windows installed within 2 weeks of start on site

Contact us to find out more

]]>

Background

For the clients, the unexpected opportunity of early retirement in 2010 was the chance to fulfil their dream of building their own low energy home which the clients quickly recognised as being a passive house timber frame build. The first challenges were finding a building plot, sorting out legal aspects and finalising planning permission and conditions, but by spring 2013, they were ready to start work. As an engineer with some DIY experience, the client drew up the plans, managed the build and carried out some of the practical work. There were numerous setbacks and crises, not least from the enormous delivery trucks blindly following their satnavs. However, the house itself went up in four days with the minimum of fuss, and the client is full of praise for the contractors, especially since the costs have proved no more than for a home to standard building regulations.

The Home

Design and materials: The timber framed house exceeds Passivhaus performance standards, and has a SAP EPC rating of A107, meaning that it is a net energy exporter. However, it is not Passivhaus certified. It was constructed by MBC Timberframe, There are no dug foundations, and the house sits on a recycled polystyrene base, with a thin (100mm) internal reinforced concrete floor slab. The frame was made off-site, and is FSC certified, with local larch cladding, at Ansty. The Ikoslate roof slates are made from recycled plastic and car tyres. Overall build cost, excluding initial site preparation, will be around £160,000 (£1230/m2 of internal floor area).

Insulation: The house faces South to make the most of solar gain. Floor insulation and wall insulation (from recycled newspapers) are 300mm, while there is 400mm in the roof. Tested air tightness was 1.22m3/h/m2 compared to 10m3/h/m2, required by Building Regulations.

Heating, ventilation and hot water: As a low energy home, it has minimal heating (~1.6kW maximum) for when the temperature reaches minus 10°C or less. A Danish Genvexmechanical ventilation and heat recovery (MVHR) system has been installed, and a small air source heat pump (ASHP) provides underfloor heating for very cold days. Hot water is provided by pre-heat from the air source heat pump, with the thermal store heated by the excess energy from the solar PV on the roof.

Windows and doors: Triple glazed from Munster Joinery. They are argon filled, soft E coated, Passivhaus Institut certified, made from sustainable timber with external aluminium cladding. U value 0.7W/m2.K.

Lighting, appliances and electricity generation: Lighting is a mix of LED downlights and low energy (CFL) wall mounted uplighters, with occupancy sensors in little used rooms. All appliances are A rated or better. The 6.25kW photovoltaic array is built into the roof, with a controller to divert excess energy to the heat store. The Client already has an electric bicycle and a partially electric car (Toyota Prius hybrid).

Water: Off-grid water supply from a private borehole, with no connection to the mains water supply, plus Bio-pure package sewage treatment plant. This choice was due to the expense of getting water and sewage to the site. However, running costs will be around £180-200 per year.

Please click here to read this client’s blog, documenting his passive house timber frame build – Wiltshire, UK

]]>Timber frame kit home using our Passivhaus build system. The project featured, vertical timber cladding, white render and natural stonework to the external facade. The project also features biomass heating in the form of a wood burning stove alongside solar thermal hot water.

The overall aesthetic is very pleasing and the client will benefit from very low energy bills for heating and hot water.

]]>Passive House Specification with Solar Thermal Hot Water

The house is 2500 sq ft house set in Co. Clare, West Ireland. The scheme used MBC’s unique twin wall system, as part of their passive house build package. The turnaround from laying the passive slab to the roof being erected and felt and battened was approximately 4.5 weeks as the client was eager to progress the build project even as the weather conditions were an issue. The building was rendered on the external face and also used timber larch cladding. The scheme featured passive windows and doors to ensure that the house U-Value remained at the passive standard.

]]>In response to the challenges of reducing emissions from building we adopt the principles of the ‘Low Carbon/Energy Hierarchy’ in our Sustainable Building system.

Reducing energy demand; through efficient design and use reduction. Energy efficiency, smart use of buildings and appliances and behaviour change are the most cost beneficial and effective means of reducing your energy bills and carbon footprint.

Energy Efficiency – Fabric First Approach

The average UK building stock looses a huge amount of energy through inefficient building fabric, the new build regulations have only just begun to recognise this by placing stricter guidelines on the thermal performance of the building fabric.

Simple Cost Effective Measures

- Increased Insulation of roofs/lofts walls and floors

- Draught Proofing/Airtightness

- Upgrading windows and Doors

- Reducing Cold Bridges and improving poorly performing elements

- Efficient lighting and appliances

- Heat recovery ventilation

The vast majority of these measures will deliver a cost benefit through saving in energy bills, however the Green Deal scheme can provide finance to help with the upfront cost of these measures.

Running Cost implications of a ‘Passive’ Fabric First Approach

The chart below illustrates how adotping an airtight, super insulated Passive approach can reduce energy bills to 10% of conventional UK stock.

Natural materials and embodied CO2

Our timber frame system is inherently more sustainable than conventional brick and block construction, we also specify natural insulation materials, finishes such as lime render, timber cladding and natural floor coverings.

]]>

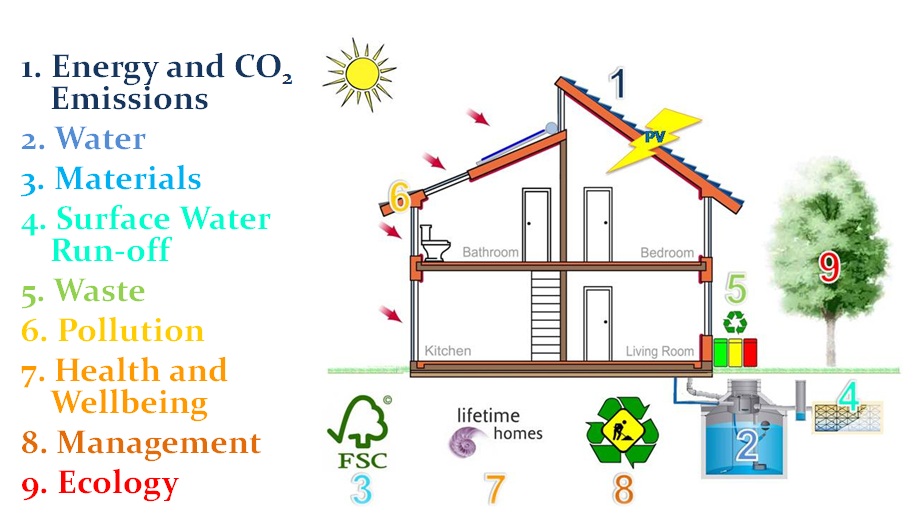

1. Energy and CO2 Emissions

SDC employ a highly insulated building envelope in our standard new build construction, with element u-values <0.15W/m2K, greatly surpassing the requirements of the Fabric Energy Efficiency Standards (FEE). In conjunction with energy efficient fixtures and mechanically ventilated heat recovery (MVHR) our new build homes will meet Code 4 of the CSH as standard.

If further reductions in Energy use and CO2 emissions up to Codes 5 & 6 are required, we specify solar thermal water heating, biomass boilers or heat pump technology. We also can specify a range of microgeneration technologies such as Photovoltaic panels, small scale wind or hydro and combined heat and power (CHP) solutions

2. Water

We specify low flow faucets and water efficient toilets as standard in our builds. To achieve Codes 5 & 6 we specify rainwater harvesting, to reduce water usage below 80L per person.

3. Materials

Timber frame systems are inherently more sustainable than conventional brick and block construction. All our housing systems use FSC certified timber and materials that have a low environmental impact, and embodied energy throughout their lifetime. Additional natural building materials can be substituted i.e. natural insulation materials, floor coverings etc.

4. Surface water run-off

We can specify a range of sustainable urban drainage solutions, including rainwater harvesting, stormwater management soakaways and permeable landscaping

5. Waste

Facility for sustainable waste management is intrinsic in our dwellings. Structure fabrication using MMC vastly reduces waste production, on and offsite.

6. Pollution

We specify insulating materials considered to have a GWP ≤5. Our preffered no combustive heating systemss MVHR, heat pump and solar thermal systems have 0 NOx emissions.

7. Heath and well-being

Our Code 6 dwellings will come with a ‘Lifetime Homes Guarantee’ . Standard dwellings have heath and well-being at the heart of their design and employ larger than average room sizes and good levels of accesses.

8. Management

Homes come with a user guide as standard, MMC techniques and our contractors ensure sustainable efficient site management with low impact.

9. Ecology

We ensure a sound ecological approach to the build and operation of the dwelling where necessary we will consult a qualified ecologist to maintain a harmonious ecological setting.

]]>